FAQ - HeadSTEP

There are two types of thermoplastic material (Maxi and Micro), what are the advantages or differences?

The thermoplastic material in Micro perforation is stronger and the holes are narrower. Therefore, it is more accurate in the repositioning of the patient. The thermoplastic material in Maxi perforation is, due to the bigger holes, more comfortable for the patient. As we know by experience, 50 percent of our customers use only the Micro masks, 30 percent use a mix of 70 Micro and 30 Maxi and 20 percent use only the Maxi perforation.

How accurate is the HeadSTEP thermoplastic based system? Do the accuracy values differ between Maxi and Micro masks?

The HeadSTEP shows under normal circumstances an accuracy of 1 to 5 mm. Publications document the high accuracy of our product. The difference between Maxi and Micro thermoplastic masks is about 2 mm.

What is the right hardening time for the mask?

After taking the mask out of the water bath it has a temperature of about 37°C, nearly body temperature. The mask cools out and stiffens after moulding and becomes a rigid replication of the patient’s anatomy.

The mask has to remain on the patient's face for a minimum of 5 minutes, below this time shrinkage is possible.

Does the impression of the mask tend to shrink during the whole treatment cycle? If so, how can this be handled?

As we know there is only little to no shrinking of the mask. If you experience shrinking you can remove the distance plate which is placed under the HeadSTEP pillow. This procedure will gain 2 mm more space for the patient. If the patient shows swelling of soft tissue you can also remove the distance plate. If the patient is loosing a lot of weight another distance plate can be put under the pillow to lift the pillow for another 2 mm.

Is the thermoplastic material biodegradable (biocompatible)?

Yes

What is the ideal temperature for the water bath?

The water bath should have 65°C/149°F and should not exceed 80°C/176°F.

How can the masks be marked?

Our customers usually put tape on the mask and mark the tape with a water resistant pen.

How are prone patients moulded into the impression?

There are 2 possibilities for patients in prone position:

1) Using the prone position pillow and moulding a mask of the back of the patient’s head in prone position.

2) Moulding the mask in supine position and using the ProneSTEP as an add on to the HeadSTEP system.

What are the benefits of the ProneSTEP compared with the prone position pillow?

The ProneSTEP needs a higher amount of time and user experience but is more accurate and precise because of the moulding of the patients nose.

If a department has only a few prone position patients a year the prone position pillow is recommended.

How many iCASTs are recommended for a start up system?

Around 40 Maxi Head, 60 Micro Head and 50 Micro Head and Shoulder.

What is the lead time for spares and thermoplastic material?

1 to 2 weeks.

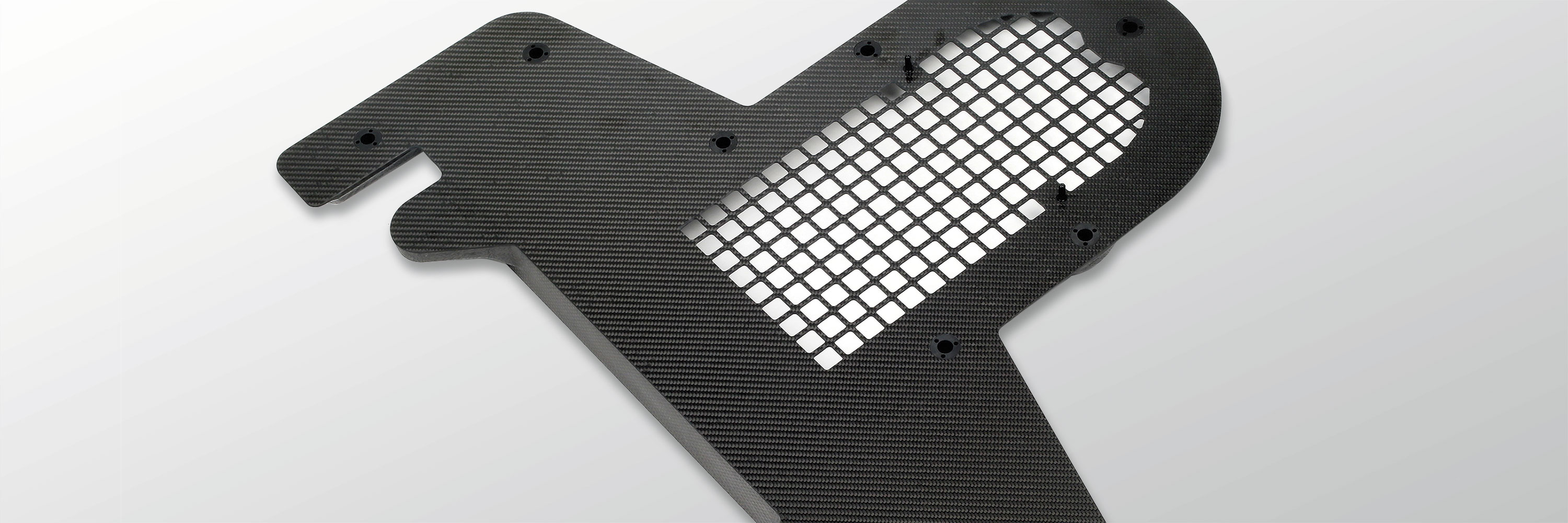

Can the HeadSTEP glass fiber only be used in the MRI scanner or can it also be used on the Linac? Is it possible to use the same iCAST frame in the CT scanner?

The glass fibre system should only be used in the MRI scanner because the glass components are causing artefacts in the CT scanner and on the Linac. The same iCAST frame and mask can be used for MRI, CT and Linac.

Is there a height adjustment for HeadSTEP glass fiber?

The HeadSTEP glass fibre is available in flat or attached with height adjustment, the standard system is with height adjustment.

What should the pillow wedge be used for?

The Pillow wedge is used to achieve a small tilt for head and neck treatment. The wedge can be placed under the standard pillow to bring the chin in an upper position. If more tilt is needed, the wedge can be used in combination with the tilt pillow.

How should the Pillow wedge be placed onto the HeadSTEP?

On the bottom there are centering discs that fit into the holes of the baseplate. On the upper side the holes are made for the centering discs of the different pillows.

What is the suggestion for superior beam techniques?

Use the HeadSTEP flat. If no HeadSTEP flat is available, it is possible to irradiate through the height adjustment which is made of hard plastic. It’s not recommended to irradiate through the metal part of the height adjustment.

Are there any limitations to using the HeadSTEP systems in a CT (bore size or table surface)?

No, the HeadSTEP has no limitations in a CT.